Product Parameter

Condition: New

Positioning Accuracy (mm): 0.01 mm

Working Table Size(mm): 1300x2500

Travel (Y Axis)(mm): 2500 mm

Spindle Motor Power(kW): 1KW

Brand Name: GXUCNC

Dimension(L*W*H): 3.15m*2.33m*1.85m

Weight (KG): 1000

Key Selling Points: High Rigidity

Machinery Test Report: Provided

Warranty of core components: 2 years

Working area: 1300mmx2500mm

Amplitude: 8MM

Air pressure: 0.6-0.8

Repeat positioning accuracy: ±0.01MM

Range of Spindle Speed(r.p.m): 1 - 24000 rpm

Number of Axes: 3

No. of Spindles: Single

Machine Type: CNC Router

Travel (X Axis)(mm): 1300 mm

Repeatability (X/Y/Z) (mm): 0.01 mm

CNC or Not: CNC

Place of Origin: Zhejiang, China

Voltage: AC380V/50HZ

Power (kW): 6

Warranty: 2 years

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufa

Video outgoing-inspection: Provided

Core Components: Motor

Name: Multi-function shaped cutting

Amplitude frequency: 10000-14000

Air speed: 50m/Min

Rail type: Taiwan high precision rail.

Transmission mode: Rack drive

Working voltage: AC380V/50HZ

Guangxu A6 cut cutting machine is mainly used for irregular cutting of non-metallic flexible materials.

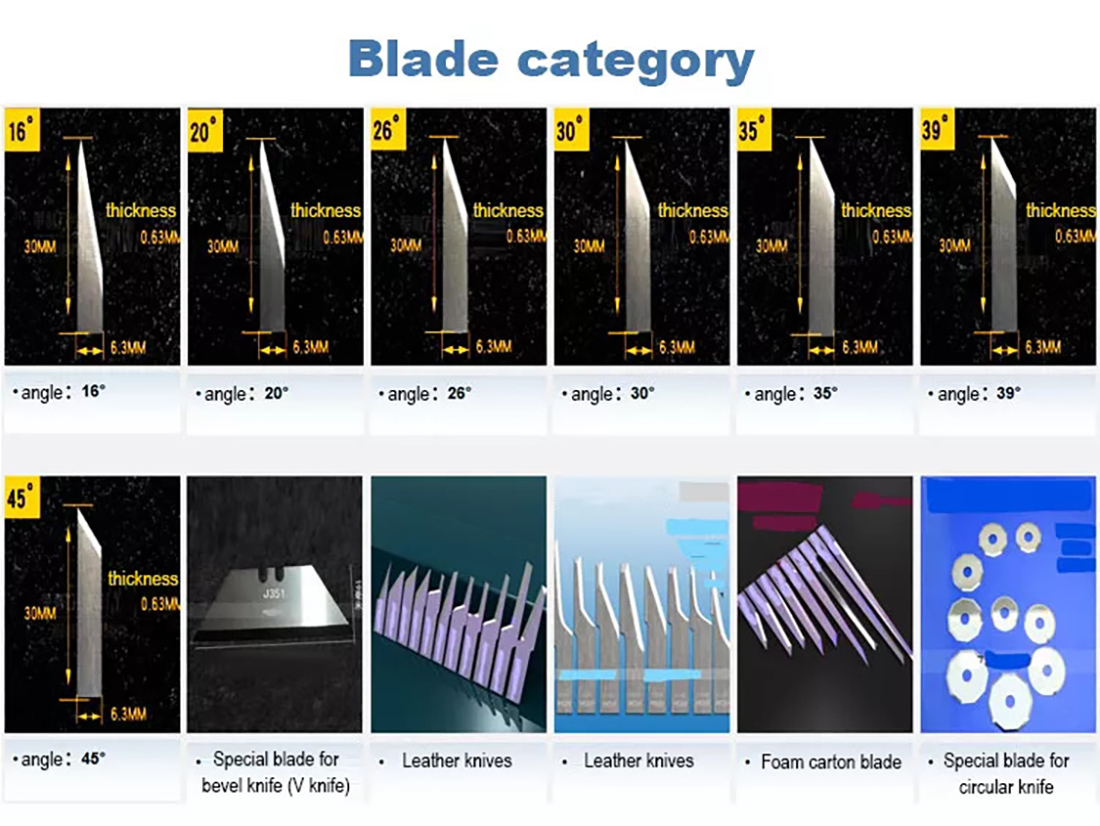

It adopts Leyu edge finding cutting software and intelligent nesting and typesetting software. It is equipped with a variety of cutting tools, such as vibrating knife,pneumatic knife, wheel cutter, indentation knife, painting pen, milling cutter, etc. it can quickly complete all kinds of processes, such as full cutting, half cutting, engraving, drilling, crease, marking, contour recognition, etc., and solve the problem of irregular drawing The cutting problem.

Appliceation Areas

The machine is widely used in advertising, seals, leather shoes, composite materials, automotive interior, clothing, carpet and other industries. According to different cutting materials, different cutters can be flexibly configured to realize the multi-purpose feature of one machine.

Typical Application

Flexible materials such as PTFE board, asbestos board, graphite composite board, rubber material, KT board, PVC foam board, leather, carpet, etc.

Machine Features

1. There is no need to open a die, and the shape can be cut arbitrarily! Smart typesetting saves materials! Cut to be consistent! High efficiency, high precision, material saving and labor saving.

2. The automatic positioning and sleeve cutting function can obtain the pattern deformation law by identifying the marking points, and optimize the original contour pattern according to the deformation amount for precise sleeve cutting.

3. Projection positioning system: Project the cutting graphics on the processing table at a ratio of 1:1, which is convenient for users to load and align; users can also place irregular parts in the projection area for alignment and cutting, which greatly improves the number of parts,utilization.

4. Blade cutting is pollution-free, odorless, green and environmentally friendly cutting; software intelligent compensation, material cutting error ±0.01mm; super automatic nesting software, material saving more than 10%.

Product Details